Grey hydrogen is produced from natural gas using a process called steam methane reforming (SMR). This process releases carbon dioxide as a byproduct, making grey hydrogen less environmentally friendly.

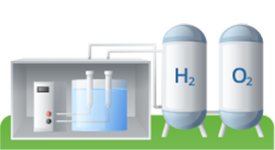

Greenhydrogen is produced through electrolysis using renewable energy sources likewind or solar power. Electrolysis splits water into hydrogen and oxygen, andwhen powered by renewables, this process results in zero carbon emissions

Blue hydrogen is also produced from natural gas, but with carbon capture and storage(CCS) technology. CCS captures and stores the carbon dioxide emissions, makingblue hydrogen a cleaner alternative to grey hydrogen.

Brown hydrogen is produced fromcoal using various methods, including gasification. This process releasessignificant carbon emissions, making it the least environmentally friendly formof hydrogen

Subject | 12-meter city bus (Hydrogen fuel Cell) | 12-meter city bus (Battery electric) | 31 ton dump-truck (Hydrogen fuel Cell) | 31 ton dump-truck (Battery electric) |

|---|---|---|---|---|

Refueling/Charging Time | ≤10Min | ≥2 H | ≤20Min | ≥2 H |

Range | 440km | 280km | 420km | 200km |

Capacity | 80 kW Fuel Cell System (6 Hydrogen Tanks,840 liters of hydrogen) | 348 kW·h | 132 kW Fuel Cell System (9 HydrogenTanks, 1485 liters of hydrogen) | 380 kW·h |

Weight | 1000kg | 2350kg | 1200kg | 2550kg |

Curb Weight (Vehicle) | 11800kg | 13000kg | 16800kg | 18000kg |

The electrolyte used in lithium battery cells contains heavy pollutants, and recycling materials like cobalt and nickel from lithium batteries is challenging. In contrast, fuel cell vehicles can be recycled without pollution at the end of their life cycle.

When the fleet size reaches over 500,000 vehicles, hydrogen fuel cell cars are predicted to cost over 30% less than lithium electric vehicles.

Lithium battery packs store energy, while hydrogen fuel cells convert energy.